Project overview

Background

The client needs a particular hanging platform to perform maintenance tasks inside a digester in Uruguay’s paper industry. The objective is to improve assembly and disassembly times compared to using multidirectional scaffolding systems.

Project

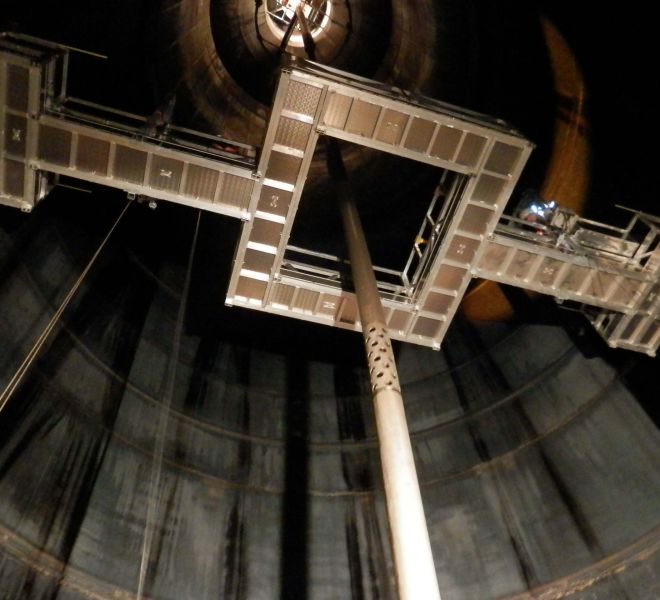

Development of equipment capable of positioning the working staff all around the digester’s interior contour; all the equipment must be disassembled and fit through a lateral manhole.

Solution

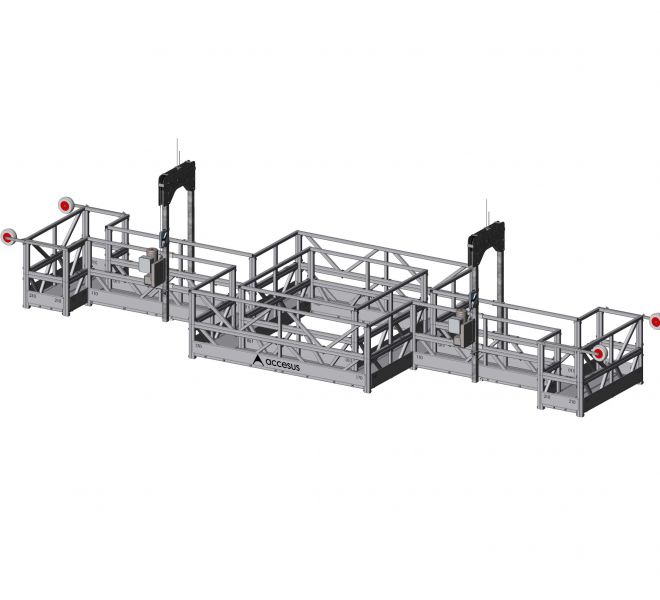

Special hanging scaffolding composed of 3 different parts:

A upper suspension structure, anchored to the tubing of the digester itself.

A metal ring is suspended from this structure, which consists of a circular rail beam on which two motorized trolleys run.

These trolleys suspend the particular hanging platform whose design with a free central space allows the passage through the digester’s central tube while enabling access to it. This platform’s extreme balconies enable reaching the digester’s whole perimeter in its internal face for its maintenance.

Accesus technicians traveled from Spain to carry out the first assembly of the equipment and to train the client.

This particular hanging platform’s work allows the digester’s maintenance in less time than with traditional scaffolding systems.