Project overview

Background

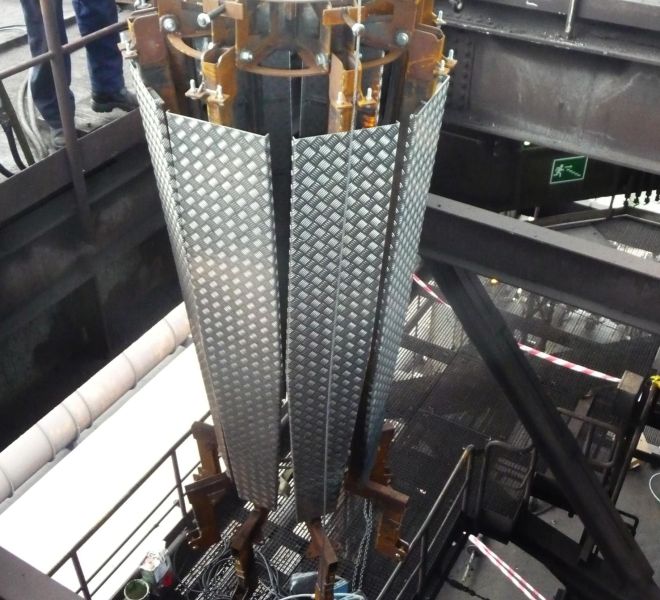

The customer requires means of carrying out repairs inside a blast furnace. All the equipment must be assembled from above, through the blast furnace’s upper entrance located on its side.

Project

Development, supply, assembly, testing, customer training, and staffing during the entire industrial shutdown of a blast furnace using a special rotating and extendable suspended platform.

Solution

We developed whole custom-made equipment, from the platform with a special T-shaped balcony with a telescopic system to the folding suspension rail to enter through the furnace’s lateral upper mouth.

The entire equipment was deployed and assembled at 30 meters-height. The working conditions inside a Blast Furnace are very hard, Our team rose to the occasion and the customer got improvements to their working time.