Project overview

Background

The customer needs equipment to facilitate changing “staves” (cooling circuit components) inside a blast furnace in a steel plant.

Project

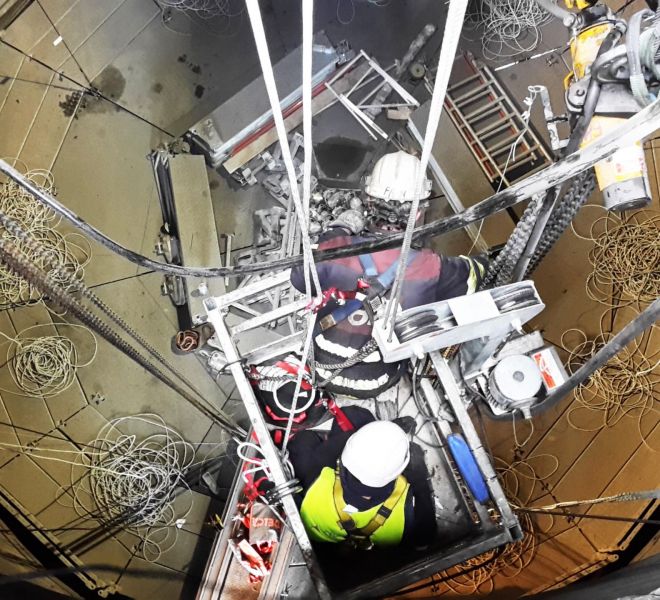

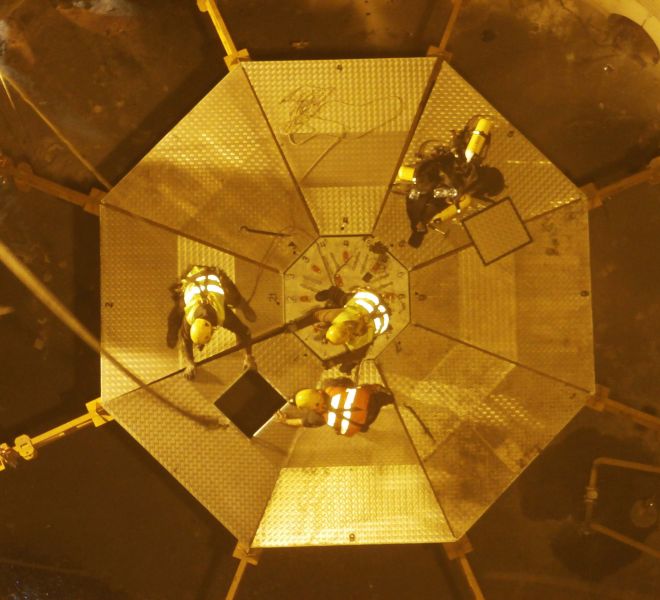

Design, supply, customer training, and assembly of equipment allow the positioning of people inside the blast furnace to access its entire interior perimeter.

Solution

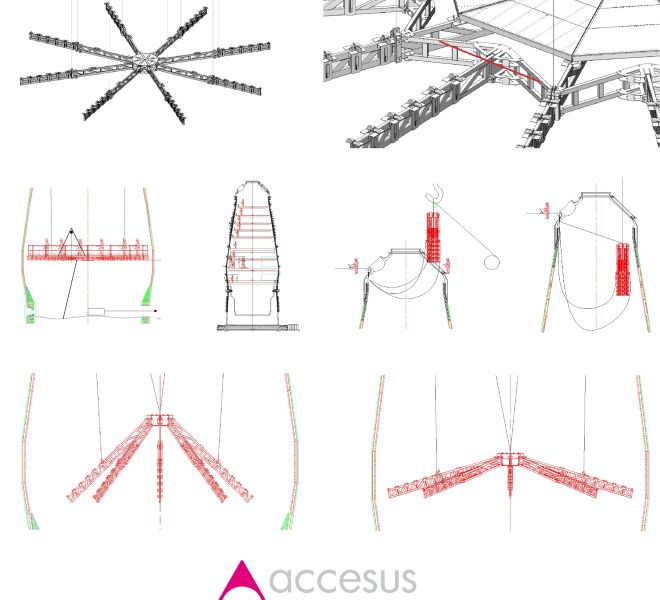

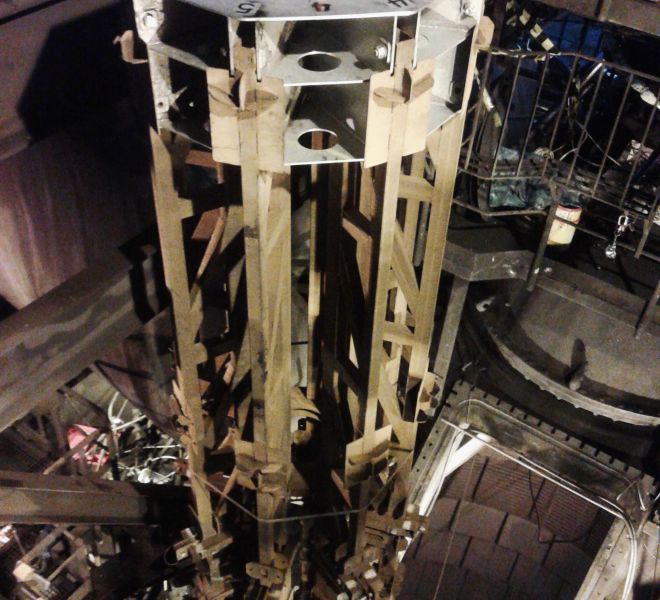

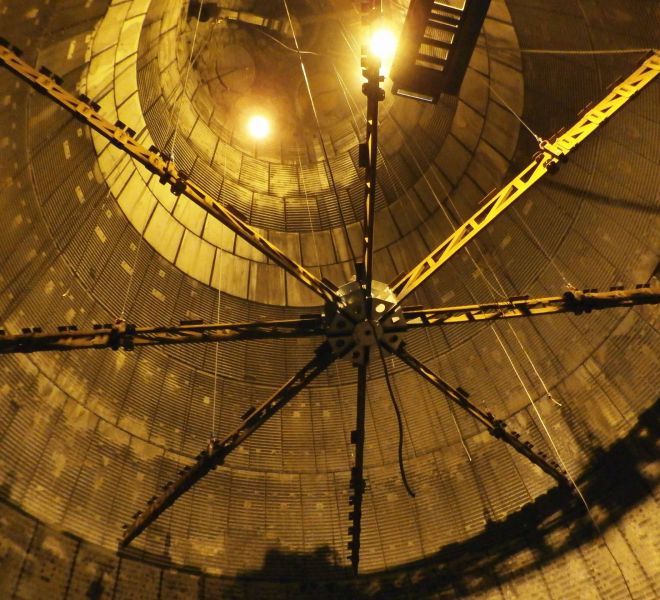

A fixed, modular, removable circular suspended platform is configured with insufficiently reduced components that allow the passage of all the equipment dismantled through the cap. The design permits a fast change of configuration in different diameters to adapt to the blast furnace’s internal diameter at each level. This provides support to the operators for the extraction and replacement of the “staves.” The whole equipment is suspended from 8 hydraulic cable traction devices.

One of the most significant difficulties and characteristics of this particular hanging platform is that it can be mounted in the air, on top of the oven.

The blast furnace was reduced by several days, among other reasons, because of the ease of assembly, disassembly, and operation with the particular Accesus hanging platform.