Project overview

Background

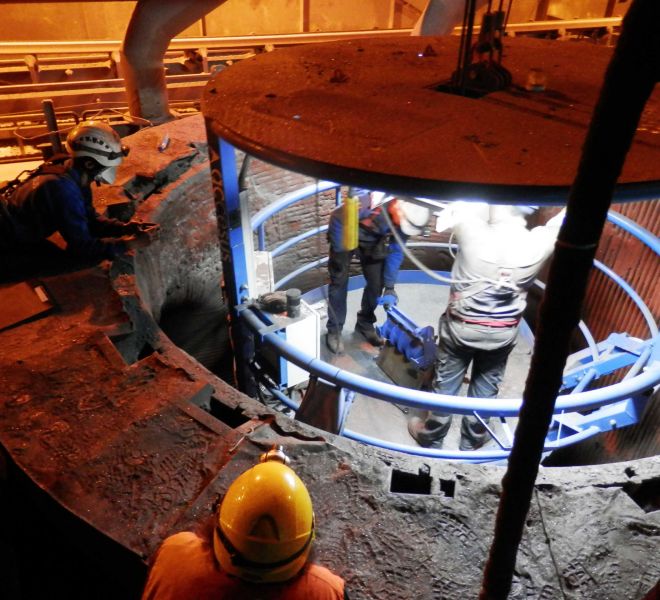

The client needs a team to carry out maintenance tasks inside the cooling ducts in the converter (BOF) at Arcelor Mittal’s steel plant in Avilés (Asturias).

Project

Design, manufacture, assembly, customer training, and annual maintenance of a particular platform allow the introduction of people inside the two boiler converters safely to perform work on the entire duct.

The duct is circular and has a height of about 60 meters, which is vertical and position inclined about 60 º.

Solution

Permanent suspension platform consisting of a suspension trolley with motorized horizontal translational movement on a rail beam. This large trolley, weighing about 5 tons, contains the lifts, fall arresters, cable, and electric hose reels, and the control and operation system of a basket that is inserted into the duct.

The basket is equipped with a cabinet to control all movements from the basket itself. A second control system allows operation from the upper carriage.

The maintenance of the BOF duct is carried out in a safe and efficient manner using a suitable platform designed to have a useful life of many years.